Revolutionizing Manufacturing with Plastic Injection Mold Parts Service

The world of manufacturing is constantly evolving, and businesses are now seeking highly efficient and cost-effective solutions. One of the most integral parts of modern manufacturing is the plastic injection mold parts service. This essential process serves as the backbone for creating durable, precise, and complex components used across various industries. In this comprehensive article, we will explore the intricacies of plastic injection molding, its advantages, and why choosing a reputable service provider like Sumiparts can significantly elevate your production capabilities.

Understanding Plastic Injection Molding

Plastic injection molding is a manufacturing process used to create parts by injecting molten plastic into a mold. This process allows for high precision and repeatability, making it ideal for producing large quantities of identical items. The procedure typically involves the following steps:

- Design of the Mold: Engineers create a 3D model of the part, after which a mold is manufactured.

- Heating the Plastic: Plastic pellets are heated until they melt into a liquid form.

- Injection of the Melted Plastic: The liquid plastic is injected into the mold under high pressure.

- Cooling and Solidification: Once the mold is filled, the plastic is allowed to cool and solidify.

- Ejection of the Part: The newly formed part is ejected from the mold, ready for finishing or assembly.

The Benefits of Plastic Injection Mold Parts Service

Utilizing a professional plastic injection mold parts service facilitates numerous benefits, including:

1. Cost-Effectiveness

When compared to traditional manufacturing methods, plastic injection molding is remarkably cost-effective. The capacity to produce large volumes of parts in a single cycle means lower labor costs and reduced material waste.

2. High Precision and Accuracy

The precision of plastic injection molding allows companies to produce intricate designs and geometries that meet exact specifications. This level of accuracy is crucial in fields such as automotive and aerospace, where component performance is critical.

3. Versatile Material Options

With advancements in polymer technology, manufacturers can choose from a broad range of plastic materials, each offering unique properties, such as flexibility, strength, and thermal resistance. This versatility makes plastic injection molding an excellent choice for many applications.

4. Enhanced Production Speed

Compared to alternative manufacturing processes, injection molding boasts a significantly faster production speed. High-speed machines can produce components in mere seconds, allowing for increased output and reduced time to market.

5. Environmentally Friendly

Modern plastic injection molding practices emphasize sustainability. Many manufacturers are adopting methods to recycle scrap plastic and reduce energy consumption, making them more eco-friendly.

Why Choose Sumiparts for Your Plastic Injection Mold Parts Service?

At Sumiparts, we understand the demands of modern manufacturing. Our commitment to excellence in plastic injection mold parts service positions us as a leader in the industry. Here are some reasons why you should consider partnering with us:

1. Expertise and Experience

Our team of seasoned professionals brings years of expertise in design and manufacturing, ensuring that every project is managed with the utmost care and precision. We leverage our knowledge to navigate the complexities of plastic injection molding efficiently.

2. State-of-the-Art Technology

Sumiparts invests in cutting-edge technology and equipment to deliver superior quality in every aspect of our service. Our advanced machinery allows us to take on both simple and complex projects with ease.

3. Comprehensive Services

In addition to plastic injection mold parts service, we offer a wide range of related services, including:

- Machining: Precision machining services for a variety of materials.

- Laser Cutting: Accurate and efficient cutting techniques for various applications.

- Welding: Strong and durable welding solutions for component assembly.

- Vulcanization: Industrial vulcanization services for rubber components.

- Industrial Supplies: A comprehensive inventory of industrial supplies to meet your operational needs.

4. Customized Solutions

We recognize that no two projects are the same. Sumiparts takes a customized approach, working closely with clients to develop tailored solutions that meet their specific needs and budgetary requirements.

5. Commitment to Quality

Quality is at the heart of everything we do. Our strict quality control measures ensure that all products meet industry standards and exceed customer expectations.

Applications of Plastic Injection Mold Parts

Plastic injection molded parts find applications across diverse industries, showcasing their versatility and adaptability. Some prominent areas include:

1. Automotive Industry

Plastic parts are fundamental in automotive manufacturing, helping to reduce vehicle weight while maintaining performance and safety. Common components include dashboards, light housings, and interior fittings.

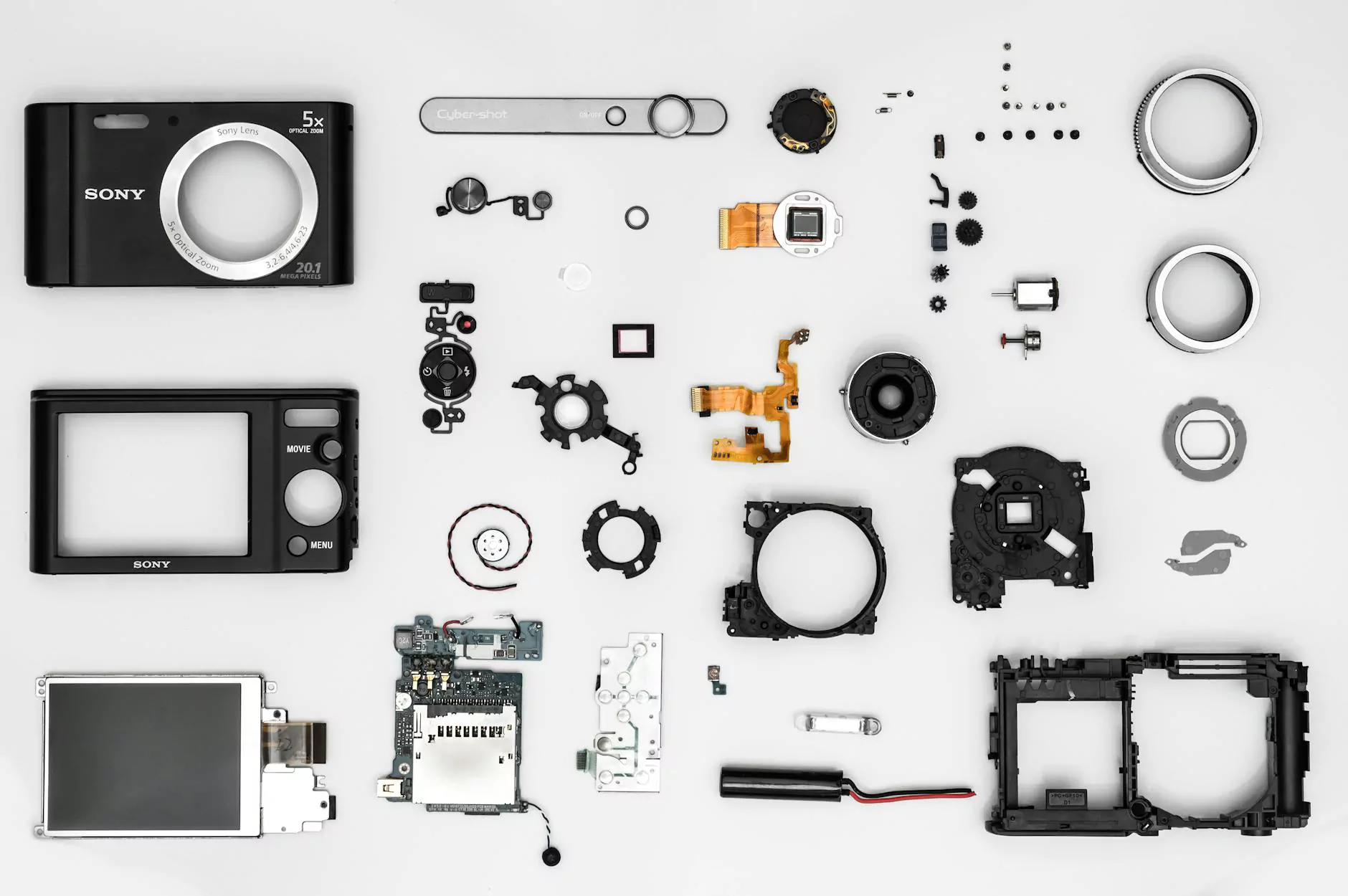

2. Consumer Electronics

The consumer electronics market relies on plastic injection molding for producing components like casings, connectors, and buttons, ensuring that products are both functional and aesthetically pleasing.

3. Medical Devices

In the medical field, precision and hygiene are paramount. Plastic injection molded components are common in devices, equipment housings, and packaging, meeting stringent regulations for safety and efficacy.

4. Packaging Solutions

Many products rely on plastic injection molded packaging to ensure durability and protection. This method allows for the creation of intricate packaging designs that are costly and difficult to achieve with other methods.

5. Industrial Applications

From equipment housings to various machinery components, industrial applications utilize a range of injected molded plastics, contributing to efficient manufacturing processes.

Choosing the Right Partner for Your Plastic Injection Mold Parts Service

Investing in a plastic injection mold parts service requires careful consideration. When selecting a partner, evaluate the following criteria:

1. Industry Reputation

Research potential providers to assess their reputation, reviews, and previous projects. A company with a strong track record is likely to deliver quality service.

2. Technical Capabilities

Ensure the provider has the necessary technical capabilities and equipment to meet your project requirements, both in terms of volume and complexity.

3. Customer Support

Choose a company that prioritizes customer support, providing clear communication and responsiveness throughout the project phases.

4. Pricing Structure

Value is important, but don't compromise quality for lower prices. Assess the overall value offered, including service quality, materials, and warranty options.

5. After-Sales Service

Inquire about any after-sales support or warranty options that may be available to address potential issues or concerns after delivery.

Future Trends in Plastic Injection Molding

The field of plastic injection molding is continuously evolving to meet changing industry standards and consumer demands. Here are some trends to watch:

1. Automation and Robotics

The integration of automation and robotics into the injection molding process is on the rise, enhancing throughput, precision, and consistency.

2. Sustainable Practices

As environmental concerns grow, manufacturers are increasingly adopting sustainable practices, including the use of biodegradable materials and energy-efficient machinery.

3. Advanced Materials

Research in material science continues to produce new polymers that offer superior strength, flexibility, and thermal properties, enhancing the capabilities of plastic injection molding.

4. Design Innovations

With the rise of 3D printing and computer-aided design (CAD), mold designs are becoming more intricate, enabling the production of components with complex geometries that were previously unattainable.

Conclusion

In conclusion, the plastic injection mold parts service is a critical component of modern manufacturing, offering unparalleled efficiency, precision, and versatility. By choosing Sumiparts as your partner, you gain access to a wealth of expertise, state-of-the-art technology, and a commitment to quality that sets us apart from the competition. As industries continue to evolve, so too will our approach to delivering innovative solutions that meet the dynamic needs of our clients. Explore the transformative potential of plastic injection molding with Sumiparts, where integrity and excellence meet.

For more information about our services and to discuss your project needs, visit sumiparts.us today!